rock well hardness test|rockwell hardness tester diagram : broker Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the . Resultados » ESPN. Classificação completa de chi.1 2024 na ESPN (BR). Saiba o desempenho de cada time.

{plog:ftitle_list}

webFairfield by Marriott Inn & Suites Uncasville Mohegan Sun Area. Hotel in Uncasville (0.6 miles from Mohegan Sun Casino) Fairfield by Marriott Inn & Suites Uncasville Mohegan Sun Area is located off of Interstate 395 in Uncasville. 8.7. Excellent. 609 reviews. Price from. $124. per night.

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test.

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the .The Rockwell hardness test method has a whopping 30 hardness scales defined by the indenter and the two loads. A Rockwell hardness value is a combination of the numerical hardness number and the Rockwell hardness .

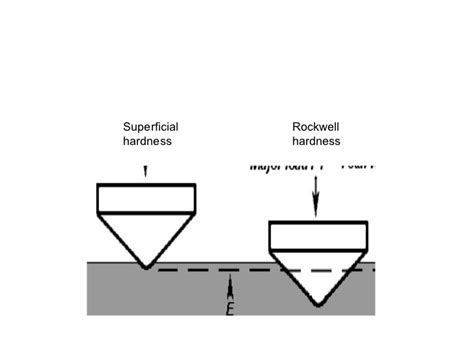

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows .High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated . The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″.The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. Significance of Rockwell Hardness. Rockwell hardness is significant because it is a quick and easy method of measuring the hardness of a material. It is also a reliable method .

Rockwell Hardness Test is one method of testing the hardness of a material and uses the Rockwell scale based on indentation hardness of a material. History of the Rockwell Hardness Tester Hugh M. Rockwell . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. .A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N. Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale . Foremost to any Rockwell test process is identification of the proper hardness scale to be used on the component to be tested. There are 30 different Rockwell scales with the majority of applications covered by the Rockwell HRC and HRB scales for testing most steels, brass, and other metals.ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520 [email protected]

rockwell hardness testing chart

rockwell hardness tester diagram

In Rockwell testing, hardness is determined by measuring the comparative depth of two carefully controlled indentations, one superimposed over the other. First a Minor Load (one of a lesser force) is applied to a steel ball or sphero—conical diamond penetrator. Then, while the Minor Load is still being applied, a Major Load (one of greater .

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.For example, a hardness value of 80 on the Rockwell A scale is reported as 80 HRA. Analytical Information. Regular Rockwell Hardness Testing- Measures the bulk hardness of the material. There are separate scales for ferrous metals, nonferrous metals, and plastics. Common Rockwell hardness scales include A, B,C and F for metals and M and R for .

rockwell hardness test theory

An indentation process, Rockwell Hardness testing is straightforward and uncomplicated in practice. Using a diamond cone or sphere-shaped indenter, a minor load is applied to a sample of the investigated material to remove any surface effects. Immediately following the minor load, a “major” load sets a force on the material for a specific .

rockwell hardness test pdf

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels.

rockwell hardness test explained

19 de jun. de 2017 · View full lesson: http://ed.ted.com/lessons/the-philosophy-of-stoicism-massimo-pigliucciWhat is the best life we can live? How can we cope with whatever the .

rock well hardness test|rockwell hardness tester diagram